Add to Cart

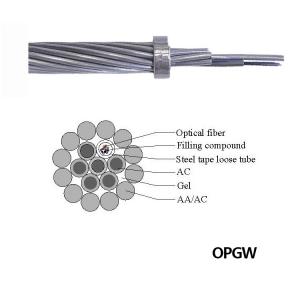

The central stainless steel tube is surrounded by single or double layers of aluminum clad steel wires(ACS) or mix ACS wires and aluminum alloy wires. are the most widely used cables ,their design is fully adapted to the most common electric line needs.

Optical Fiber Characteristics

The optical, geometrical, mechanical and environment characteristics of the ITU-T G.652.D optical fiber shall be accordance with below table:

| Characteristics | Specified Values | Units | ||

| Optical Characteristics | ||||

| Mode field diameter | at 1310nm | 9.1±0.5 | µm | |

| at 1550nm | 10.3 ± 0.7 | mm | ||

| Attenuation coefficient | at 1310nm | ≤0.36 | dB/km | |

| at 1550nm | ≤0.23 | dB/km | ||

| Attenuation non-uniformity | ≤0.05 | dB | ||

| Zero dispersion wavelength ( λ0) | 1300 ~1324 | nm | ||

| Max zero dispersion slope (S0max) | ≤0.092 | ps/(nm2·km) | ||

| Polarization mode dispersion coefficient(PMDQ) | ≤0.2 | |||

| Cut-off wavelength (λcc) | ≤1260 | nm | ||

| Dispersion coefficient | 1288~1339nm | ≤3.5 | ps/(nm·km) | |

| 1550nm | ≤18 | ps/(nm·km) | ||

| Effective group index of refraction (Neff) | at 1310nm | 1.466 | - | |

| at 1550nm | 1.467 | - | ||

| Geometric characteristic | ||||

| Cladding diameter | 125.0±1.0 | µm | ||

| Cladding non-circularity | ≤1.0 | % | ||

| Coating diameter | 245.0±10.0 | µm | ||

| Coating-cladding concentricity error | ≤12.0 | µm | ||

| Coating non-circularity | ≤6.0 | % | ||

| Core-cladding concentricity error | ≤0.8 | µm | ||

| Cladding / coating concentricity error | ≤12.0 | µm | ||

| Mechanical characteristic | ||||

| Curling | ≥4 | m | ||

| Proof stress | ≥0.69 | GPa | ||

| Coating strip force | Average value | 1.0-5.0 | N | |

| Peak value | 1.3-8.9 | N | ||

| Macro bending loss | Ф60mm, 100 circles, at 1550nm | ≤0.05 | dB | |

| Ф32mm, 1 circles, at 1550nm | ≤0.05 | dB | ||

Specification of OPGW

| Items | Technical Data | ||

| Stranded | Core, layer 1, layer 2 | ||

| Stranding direction | Outer layer is right hand | ||

| Cable diameter (Nominal) | 20.0mm | ||

| Cable Weight (Approx.) | 1365kg/km | ||

| Supporting Cross Section | AS Wire | 188.5mm2 | |

| Rated Tensile Strength (RTS) | 205kN | ||

| Modulus of Elasticity (E-Modulus) | 162.0kN/mm2 | ||

| Thermal Elongation Coefficient | 13.0×10-6/K | ||

| Maximum Working Stress (40%RTS ) | 82.0kN | ||

| Everyday Stress(EDS)(18%~25%RTS) | 36.9~51.25kN | ||

| DC Resistance at 20℃ | 0.442 ohm/km | ||

| Short time current (1.0s, 40℃~200℃) | 13.62kA | ||

| Short time current Capacity I2t | 185.4kA²s | ||

| Minimum bending radius | Installation | 30 times of cable diameter | |

| Operation | 15 times of cable diameter | ||

| Temperature Range | Installation | -10℃~+60℃ | |

| Storage & shipping | -40℃~+60℃ | ||

| Operation | -40℃~+80℃ | ||

Fiber and Loose Tube Color Identification

The individual fiber and loose tubes shall accordance with standard TIA/EIA-598-A and the color code as below.

Steel tube 1 (No.1-12 fibers) : Single mode optical fiber (SM)

Fiber Colors

| NO. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Blue | Orange | Green | Brown | Grey | White | Red | Nature | Yellow | Violet | Pink | Aqua |

Steel tube 2 (No.13-24 fibers) : Single mode optical fiber (SM)

One black tracer (50mm pitch)

| NO. | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| Color | Blue | Orange | Green | Brown | Grey | White | Red | Nature | Yellow | Violet | Pink | Aqua |

Steel tube 3 (No.25-36 fibers) : Single mode optical fiber (SM)

One black tracer (100mm pitch)

| NO. | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 |

| Color | Blue | Orange | Green | Brown | Grey | White | Red | Nature | Yellow | Violet | Pink | Aqua |

Steel tube 4 (No.37-48 fibers) : Single mode optical fiber (SM)

One black tracer (150mm pitch)

| NO. | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 |

| Color | Blue | Orange | Green | Brown | Grey | White | Red | Nature | Yellow | Violet | Pink | Aqua |

Packing and Shipping

The OPGW shall be tightly and uniformly wound on a strong wood-iron reel which conforms to ANSI/AA 53-1981 or equal. The reel shall be lagged with stout wood-iron battens so as to prevent the OPGW from damage in ordinary shipping, handling, storage and stringing operations.

According to length of cable, we choose different type reel (D,d,b,w1,w2) for loading cable.

Dongguan TW-SCIE Co., Ltd. is a high-tech enterprise specializing in the research and development, production, processing, sales and network engineering of optical fiber communication products, and has independent import and export rights. The company has a group of loyal, dedicated, wise, strong professional and technical talents, committed to tracking the world's advanced optical communication products development and application. The company R & D, production, management of the main products are optical fiber, optical cable, optical transceiver, optical MODEM and so on. Products are widely used in communication, electric power, railway, military and other related departments, exported to France, India, Singapore, Malaysia and other countries.

Dear Valuable Customer,

Thank you for choosing our company. Your choice is our direction and motivation.

TW-SCIE will continue offers her customers Top Quality; Technical expertise; Reasonable Prices; & Short delivery Time. These qualities have contributed to the growing number of satisfied customers.

Your sincere,

TW-SCIE

ANY QUESTIONS , PLEASE FEEL FREE TO CONTACT US !