Add to Cart

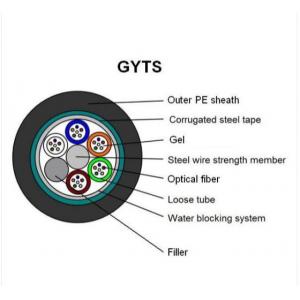

GYTS 12 Core Single Mode Armoured Duct and Aerial Fiber Optic Cable

General

This specification covers the design requirements of structure, mechanical, physical and performance standards for the supply of optical fiber cables. The features described in this document are intended to provide information on the performance of optical cable.

Specifications

General Specifications

| Cable Type | GYTS |

| Fiber Type | G652D |

| Application | Long-distance communication, LAN |

| Recommended installation methods | Duct or aerial |

| Environment | Outdoor |

| Temperature Range | -40℃ to 70℃ |

Fiber Specifications

| Technical parameter of ITU-T G.652D (B1.3) single-mode optical fiber | |||

| Optical Characteristics | |||

| Mode field diameter (MFD) | 1310nm 1550nm | 9.2±0.4 10.4±0.8 | µm µm |

| Cut-off wavelength (λcc) | ≤1260 | nm | |

| Attenuation coefficient | 1310nm 1383nm 1550nm | <0.35 <0.35 <0.22 | dB/km dB/km dB/km |

| Macro bending loss | φ75mm, 100circles, at 1550nm | ≤0.1 | dB |

| Attenuation non-uniformity | ≤0.05 | dB | |

| Dispersion coefficient | 1288~1339nm 1271~1360nm 1550nm | ≤3.5 ≤5.3 ≤18 | Ps/(nm.km) Ps/(nm.km) Ps/(nm.km) |

| Zero dispersion wavelength | 1300~1324 | nm | |

| Max zero dispersion slope | ≤0.093 | Ps/(nm2.km) | |

| Group index of refraction (typical value) | 1310nm 1550nm | 1.466 1.467 | |

| Geometric characteristic | |||

| Cladding diameter | 125.0±1.0 | µm | |

| Core/cladding concentricity error | ≤0.8 | µm | |

| Cladding non-circularity | ≤1.0 | % | |

| Coating diameter | 245.0±10 | µm | |

| Cladding/coating concentricity error | ≤12.0 | µm | |

| Coating non-circularity | ≤8 | % | |

| Diameter of colored coating | 250.0±15 | µm | |

| Mechanical characteristic | |||

| Curling (radius) | ≥4 | m | |

| Proof stress | >0.69 | Gpa | |

| Coating strip force | Average value Peak value | 1.0-5.0 1.3-8.9 | N N |

| Dynamic stress corrosion susceptibility parameter (nd value) | ≥20 | ||

Standard Color Identification of Fiber

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Slate | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Pink | Aqua |

Cable Design

| Item | Description | ||||||||||

| Model No | GYTS | ||||||||||

| 1. Fiber count | 2-6 | 12 | 24 | 36 | 48 | 72 | 96 | 144 | |||

| 2. Cable Diameter(MM) | 8.8±0.2 | 9.1±0.2 | 9.6±0.2 | 10.2±0.2 | 11.7±0.2 | 14.2±0.2 | |||||

| 3. Cable Weight(KG) | 82 | 96 | 120 | 140 | 203 | ||||||

| 4. Central Strength member | |||||||||||

| -Material | Steel wire | ||||||||||

| -Diameter | 1.4mm | 2.0mm | |||||||||

| -PE sheath | No | Yes | |||||||||

| 5. Loose Tube | |||||||||||

| -Material | PBT | ||||||||||

| -Type of filling compound | Jelly | ||||||||||

| -No. of loose tube | 1 | 2 | 4 | 3 | 4 | 6 | 8 | 12 | |||

| 6. Filler | |||||||||||

| -Material | PP | ||||||||||

| -No. of fillers | 4 | 3 | 1 | 2 | 1 | 0 | |||||

| 7. Tube Assembly | |||||||||||

| -Tube Layout | 1+5 | 1+6 | 1+8 | 1+12 | |||||||

| -Stranding type | SZ | ||||||||||

| 8. Water-blocking system | |||||||||||

| -Material | Filling compound | ||||||||||

| 9. Armour | |||||||||||

| -Material | Steel tape | ||||||||||

| 10. Outer Sheath | |||||||||||

| -Material | PE | ||||||||||

| -Thickness | 1.5mm±0.2mm | ||||||||||

| 11. Sheath marking | |||||||||||

| -Type of marking | Laser printing | ||||||||||

Cable Structure

| Item | Description | |

| Tensile strength(N) | Long-term | 600 |

| Short-term | 1500 | |

| Crush(N/100mm) | Long-term | 300 |

| Short-term | 1000 | |

| Min. Bend Radius | Static | 10D |

| Dynamic | 20D | |

| Temperature Range(℃) | Operation | -40℃ - +70℃ |

| Installation | -10℃ - +60℃ | |

| Storage | -40℃ - +70℃ | |

Cable Sheath Marking

Each cable have the following information clearly marked on the outer jacket of cables:

a. Name of manufacturer.

b. Year of manufacturer

c. Type of cable and fiber

d. Length mark (printing on each meter normally)

e. Or as customer’s requirements.

Cable Performance

| Item | Testing | Test Method | Test Result |

| 1 | Tensile strength IEC 60794-1-E1 | Tension load:1500N Time: 1min Cable length: ≥50m | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 2 | Impact IEC 60794-1-E4 | Height: 1m Weight: 1kg Impact spot: ≥5 Impact cycle: at lease 3 cycle per spot | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 3 | Repeated Bending IEC 60794-1-E6 | Bending diameter: 25X the cable outer diameter Applied load: 25kg Bending cycle: 30times Bending speed: 1 cycle per 2s | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 4 | Torsion IEC 60794-1-E7 | Torsion length: 1m Applied load: 25kg Torsion angle: ±90 or +180 Twist cycle: ≥10 times | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 5 | Water Penetration IEC 60794-1-F5B | Water height: 1m Cable length: 3m Keeping time: 24hours | No water leaked from the opposite end of cable |

| 6 | Temperature IEC 60794-1-F1 | Temperature step:+20°C->-40°C°C >+70°C->+20°C Keeping time: 24hours per each step Cycle:2times | Loss change≤0.1dB@1550nm No fiber break and no sheath damage |

| 7 | Compound flow IEC 60794-1-E14 | Sample length: 30cm Keeping time: 24hours | No compound flow |

Packing & Shipping

Cable is supplied in lengths as specified in PI or as requirement. Each length will be shipped on a separate non-returnable wooden drum. The minimum barrel diameter of the drum will not be less than 30 times the cable diameter.

The cable on each reel will be completely covered with a thermal wrap which is fastened to the cable by packaging straps. This wrap is reusable and provides excellent thermal and UV protection.

The cable ends will be sealed with plastic protection caps to prevent water penetration. The ends will be easily accessible for testing. A final inspection test report with attenuation performance data for each fiber is attached inside the drum.

Company Profile

Dongguan TW-SCIE Co., Ltd.is located in Qingxi Town, a beautiful industrial town in Dongguan City, Guangdong Province, and also have other place in Deyang Sichuan .covering an area of more than 10,000 square meters, with more than 200 employees. Since its inception, the company adheres to the concept of "continuous innovation, the pursuit of excellence", the integrity of the enterprise, accurate positioning, long-term commitment to the development of optical fiber communication products and market expansion. Nowadays, Tewang has a modern office environment, advanced production equipment and a group of high-quality scientific research and technical personnel and management personnel, and has become a fiber optic communication products research and development, production, sales and network engineering as a whole, and has the right to import and export the emerging high-tech enterprises.